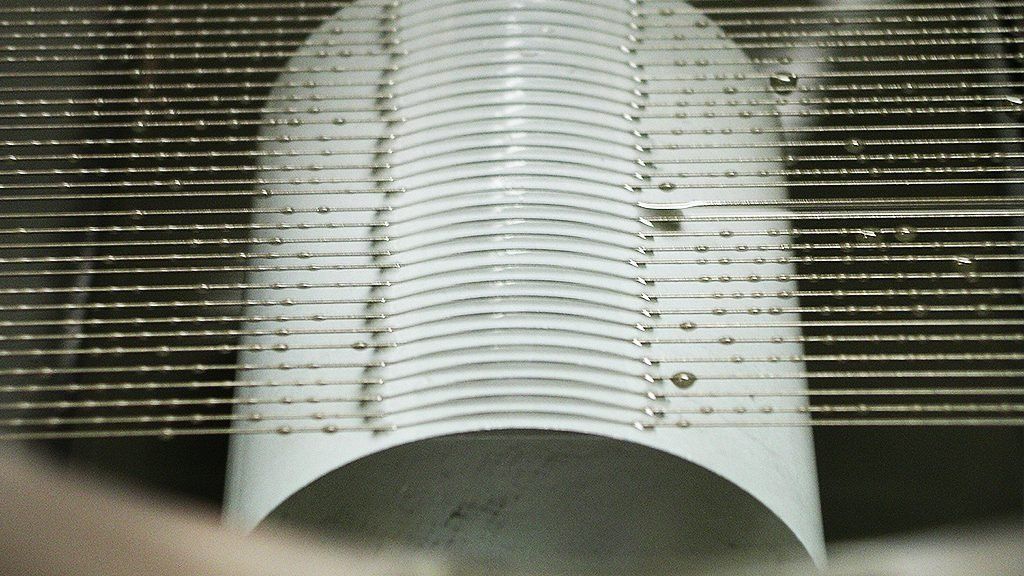

Wire Sawing

Wire sawing is an intricate and precise cutting technique widely used in the semiconductor industry and various construction applications. At GTI Technologies, our thin wire saw-cutting method utilizes a thin, tensioned wire to slice through materials, offering a level of precision that other cutting methods cannot match. Wire saws are especially valuable for their ability to cut through hard materials with minimal damage to the workpiece. In industries where the accuracy of the cut and the quality of the finish are paramount, wire sawing stands as the preferred choice due to its efficiency and the high degree of control it provides to the operator.

What to Look for in Thin Wire Saws

When considering thin wire saws for your cutting needs, there are several factors to focus on to ensure you select the best equipment. Thin wire saws should provide consistent performance and using our supplier of manufacturing equipment known for its reliability is key to achieving clean, precise cuts. The quality of the multi-wire saws is also crucial; they should be capable of operating at the necessary speed and tension without compromising the integrity of the material. Additionally, cable saws can be an effective solution for larger-scale construction projects, where their strength and durability become essential. Lastly, consider metal cutting wire options for their flexibility in handling diverse materials and complex cutting jobs.

Our Process

01.

Work together with our customers and suppliers to clearly understand the application and our customer’s needs and potential solutions.

02.

Test our preferred solution, evaluate with the customer.

03.

Present and then deliver solutions on-time.

04.

Support our customers with training, spare parts, and ongoing engineering resources.

Choose Our Premium Wire Saws

If you require outstanding performance and durability for your cutting tasks, choose our premium wire saws. Our wire sawing solutions are engineered to meet the high standards of modern manufacturing and construction, ensuring that every cut is as precise and clean as the last. We are committed to supplying the best in thin wire saw technology. For the semiconductor industry, where extreme precision is non-negotiable, the implementation of specialized diamond wire technology ensures the highest level of accuracy. Ready to make a decision, or do you need more details? Contact our team today to discuss your needs with our team of experts. We will provide you with detailed information and a personalized approach to ensure you receive the perfect wire saws for your project's success.

Contact us

Hours

Monday - Friday: 8AM-5PM

Service Area

6 Armstrong Road,

Shelton, CT 06484, USA