GRINDING

GTI offers mulitple solutions for the grinding of hard, crystalline materials like SiC.

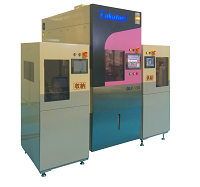

The Takatori GLP tools provide a very rigid platform for wafer grinding of SiC and other hard materials.

Takatori's grinding platforms are built for enhanced rigidity, leading to high wafer quality and high throughput even on the most demanding applications.

| Machine | Work Size/Wafer Size | Grinding Wheel Size | Machine Dimensions (WxDxH) |

|---|---|---|---|

| GLP-150 | Up to 150mm | Max Φ300mm | 900 x 2,280 x 1,940mm |

| GLP-200W | Up to 200mm | Φ200mm or Φ300mm | 3,000 x 1,400 x 2,400mm |

| GLAPPING-SiC | 200mm | Φ280mm or Φ300mm | 1,225 x 2,500 x 2,500mm |

GLP-150:

This grinding machine is capable to grind hard brittle material like SiC, GaN, and sapphire. The machine will grind with heavy load, which leads to less grinding time, higher accuracy, and long life of grind stones. Grindstone will last longer with shorter grinding time by using non-dress grindstone. The machine uses graphical user interface (GUI) which is user-friendly, and able to set data flexibly.

GLP-200W:

This new grinding machine is 2-head and 3-tables model with high rigidity to grind hard and brittle material like SiC, GaN, LT/LN and sapphire. The machine also has a precise in-process gauge (non-contact in-process gauge as an option). It will have best function for grinding the laminated thin wafer etc. It has smaller motor capacity by using servo-motor, which also means less irregularity of spinning that leads to stabilization of grinding face.

GLAPPING-SiC

The latest wafer grinding platform from Takatori is their innovative Glapping machine. This tool is designed with Takatori's uniquely rigid structure, and adds enhanced automation features to improve performance.