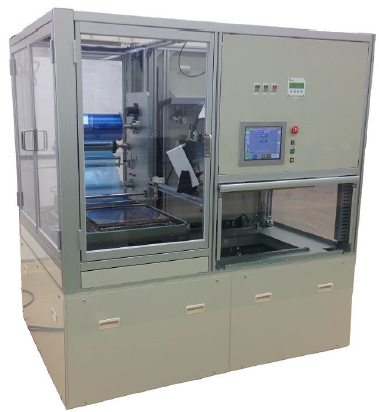

Film Laminator

How to Use a Film Laminator

Operating a film laminator effectively involves understanding its mechanics and the types of lamination it can perform. In processes requiring dry film lamination, a film laminator must accurately apply layers without the use of solvents or liquids, which is a critical specification for certain electronic applications. The range of sophisticated equipment we provide as a renowned supplier of manufacturing equipment is designed to support these needs.

Vacuum lamination from The Takatori Team

When working with delicate semiconductor components, a reliable semiconductor equipment system capable of vacuum lamination ensures a bubble-free and firm adhesion. Moreover, our tape lamination processes are streamlined using our advanced film laminators. This is highly important as it enhances the protection and functionality of semiconductor wafers with precision wafer lamination techniques. Some of the vacuum lamination machines we offer include:

| Machine | Wafer size | Lamination type | Machine size (WxDxH) |

|---|---|---|---|

| TEAM-100ARF | Up to 200mm | Vacuum | 1,490x1,190x1,660mm |

| TEAM-300ARF | Up to 300mm | Vacuum | 2,100x2,250x2,300mm |

| VTM-150M | Up to 150mm | Vacuum | 1,300x750x1,750mm |

| VTM-200M | 150, 200mm | Vacuum | 1,600x950x1,800mm |

| VTM-300 | Up to 300mm | Vacuum | 1,690x2,950x1,850mm |

| VTM-300MA | Up to 300mm | Vacuum | 1,870x1,150x1,850mm |

- TEAM-100ARF - Full-Automatic Dry-resistant film Laminator will laminate film in a vacuum chamber which will prevent bubbles on the film or damage to the wafer. The tool also separates tape cutting from lamination, allowing for “inner cut” lamination and making multi-layer lamination possible.

- TEAM-300ARF - Laminate dry photoresist and other advanced films for wafer bumping, MEMS, TSVs, and other advanced packaging applications. The machine laminates in the vacuum chamber for the highest quality and no micro-bubble, even around complex surface features. The machine also separates tape cutting from lamination, protecting the wafer edge and allowing a smaller diameter tape circle.

- VTM-300A - Takatori’s most capable, flexible laminator, the VTM series machines are capable of different types of lamination, including vacuum. The machine can laminate different types of films, including dry and non-conductive films (NCF).

- VTM-300MA - The semi-automatic version of the VTM-300A, the “M” version, is manually loaded and features the same lamination capabilities as the fully automatic machine. This machine also adds the capability to mount wafers, making it a very flexible option.

ATMOSPHERIC LAMINATION

Besides vacuum lamination solutions, Takatori also offers another renowned lamination product for its customers. This process is known as atmospheric lamination. Do you want to learn more about us? Here are the different types of atmospheric lamination machines that we offer:

| Machine | Wafer size | Lamination type | Throughput | Machine size (WxDxH) |

|---|---|---|---|---|

| ATM-1100K | Up to 200mm | Atmospheric | Up to 50wph | 1,030x1,340x1,750mm |

| ATM-1100KA | Up to 200mm | Atmospheric | Up to 50wph | 1,030x1,340x1,750mm |

| DM-800B | 150, 200mm | Atmospheric | Up to 25wph | 1,330x1,080x1,930mm |

| DM-812M | 200, 300mm | Atmospheric | --- | 1,350x910x1,250mm |

- ATM-1100K - Takatori’s most advanced atmospheric laminator features highly refined temperature and pressure controls to ensure high-quality lamination of advanced films.

- ATM-1100 KA - The ATM-1100KA is a cost-effective solution for the atmospheric lamination of dry films and other tapes. It features many of the same capabilities as the ATM-1100K but is a simpler tool at a lower price. It is also a good solution for tenting applications.

- DM-800 Backside Lamination - A specialized lamination tool for backside lamination of single-layer die attach film (DAF) onto wafers. The machine is designed to safely handle wafers down to 50 microns, and to work with thin, delicate DAF tapes.

- DM-812M - The semi-automatic machine for dicing-die bonding film for up to 300mm wafer. Applicable for ultra-thin wafers less than 50 microns with a wafer support system.

Order Dry Film Lamination

Our top-of-the-line film laminators are here to provide the quality and reliability your project demands, especially when it comes to dry film lamination. With our cutting-edge technology, you can achieve flawless results and superior product durability, ensuring each layer adheres perfectly every time. Please contact us for personalized advice or assistance with selecting the right lamination solution. Our expert team is committed to helping you optimize your production process with industry-leading lamination technology.