MULTI WIRE SAWS

ABOUT

Multi wire saws are essential for the precision slicing required in semiconductor manufacturing. At GTI Technologies, we are known for the efficiency and ability to produce high volumes of wafers with uniform thickness, which is integral in producing high-quality electronic components. Innovations in multi wire saw technology have allowed for significant advancements in the semiconductor industry, ensuring that the wafers produced are cut to exact specifications with minimal material loss. Manufacturers can optimize their operations, reduce waste, and maintain a competitive edge in the fast-paced electronic market by selecting the best multi wire saws.

TAKATORI MULTI WIRE SAWS

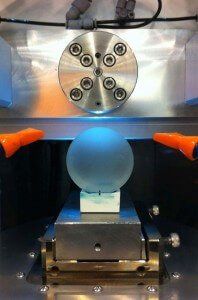

Takatori is the world leader in slicing challenging materials using diamond wire or abrasive slurry. GTI and Takatori worked together to develop the first applications to slice sapphire and silicon carbide using wire saws, and today, Takatori saws are industry standards for both materials. From the beginning, Takatori gave their machines a unique “rocking” function, improving slicing quality. Almost all of today’s Takatori saws still have this feature, and it opens the door not just to higher quality but auto-winding, speeding up the turn-around of the machine. GTI and Takatori have helped customers achieve lower costs and higher productivity by slicing various materials, including SiC, sapphire, GaN, glass, ceramics, GaAs, GaP, quartz, Si, and more.

CHOOSE OUR INDUSTRY-LEADING MULTI WIRE SAWS

It's time to revolutionize your manufacturing process with our industry-leading multi-wire and dicing saws. By incorporating our superior technology your production line will see improved yield, greater precision, and enhanced cost-efficiency. Let us be the partner that elevates your operations to the next level. For more information on our products and services or to discuss how our saws can be integrated into your projects, please feel free to Contact us.