Takatori Semiconductor Equipment

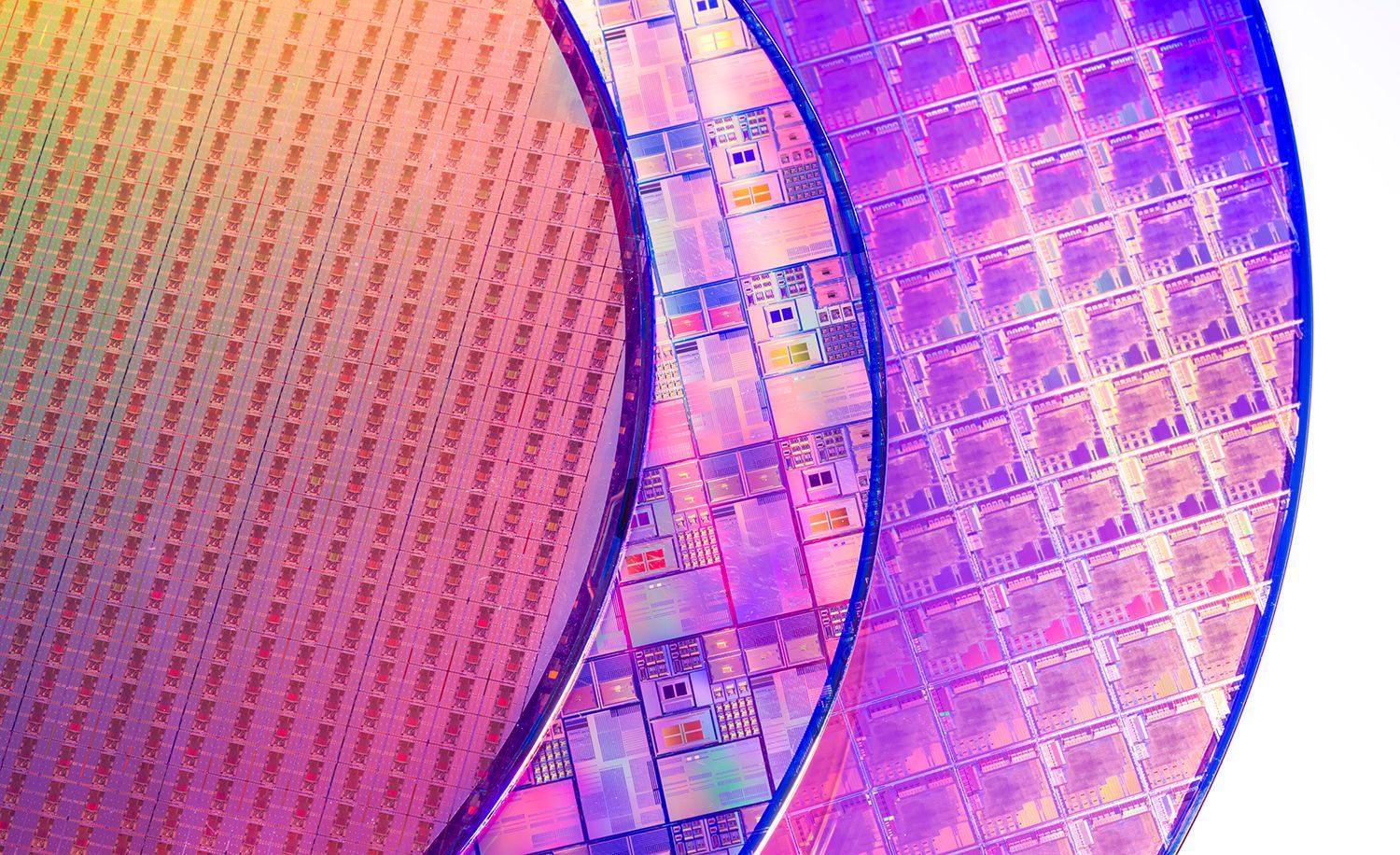

The semiconductor equipment that powers the dynamic and ever-evolving tech industry is a cornerstone of modern electronics. At GTI Technologies, we understand that at the heart of the digital age, these sophisticated pieces of machinery enable the production of the intricate and tiny components found in smartphones, computers, and countless other devices. As demand for smaller, faster, and more efficient electronic devices grows, the need for high-quality semiconductor manufacturing equipment becomes ever more critical. Bringing these complex components to life requires precision engineering and innovative technology, ensuring that every chip meets the high standards required by the industry.

What Are the Core Components of Semiconductor Equipment?

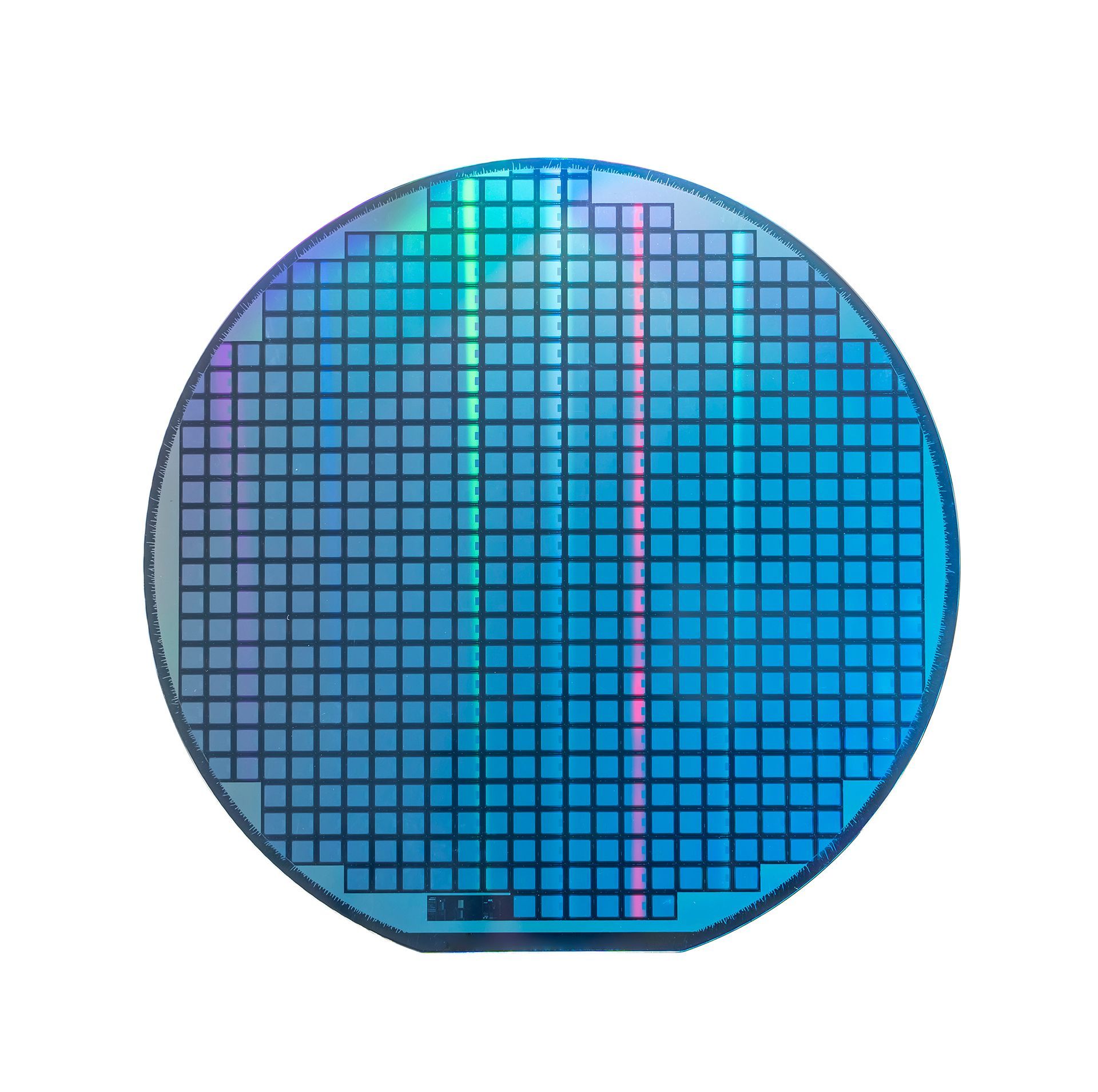

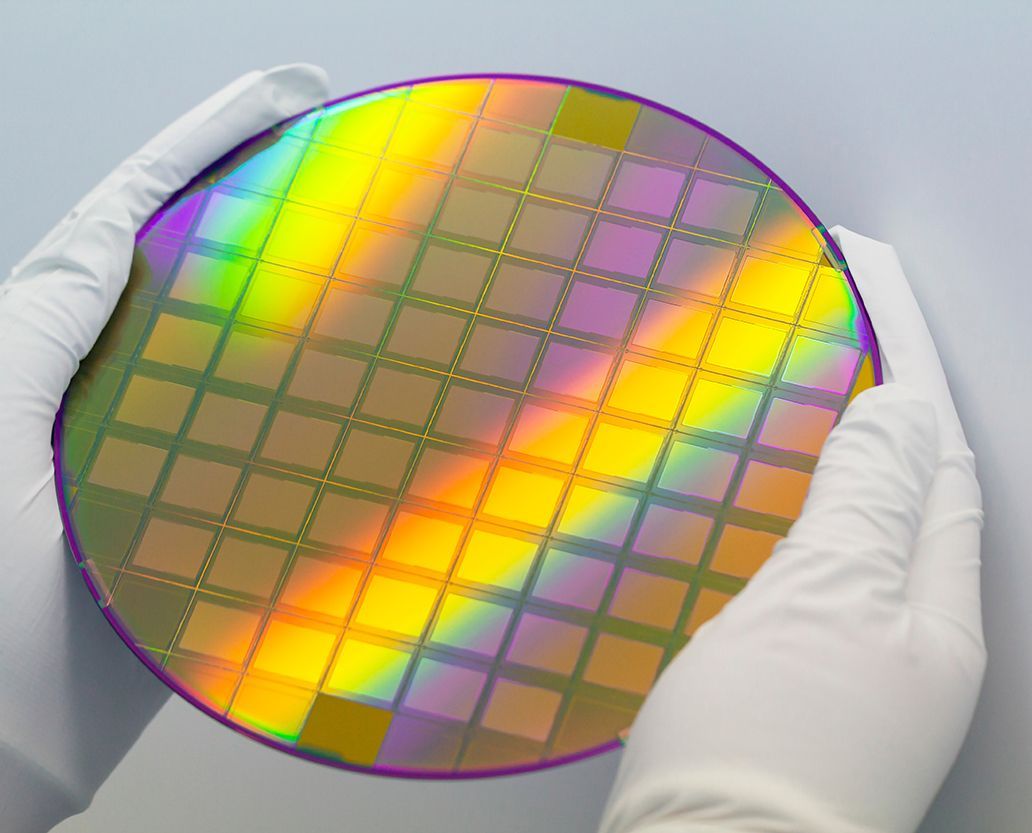

Delving deeper into the heart of semiconductor equipment, one would find an array of specialized machinery designed for impeccable precision and reliability. Producing semiconductor devices involves several critical steps, including supplier manufacturing equipment for efficient and accurate production. From intricate circuit patterning to the final assembly, the variety of equipment includes multi-wire saws for slicing wafers with exactitude.

Takatori Semiconductor Equipment

For 25 years, Takatori has been delivering machines to the semiconductor industry. Their core application is protective tape lamination before back grinding and tape removal after grinding and wafer mounting. In this area, Takatori can provide solutions for the most demanding thin-wafer applications, including Taiko. Takatori has gained decades of expertise in this area and expanded to the lamination of advanced films, including dry film, DAF, and NCF. They also offer specialized equipment for wafer bonding, UV exposure, and metal lift-off.

Our vacuum lamination processes also provide clean environments crucial for delicate semiconductor fabrication. Protecting the wafer surface during thinning is essential, achieved using backgrind tape, which serves as a safeguard. Our wafer lamination technologies also play a pivotal role in encapsulating and protecting semiconductor wafers, showcasing semiconductor manufacturing equipment's comprehensive range and integral nature.

Discover Precision with Our Equipment

With a firm commitment to innovation and quality, we invite industry professionals and businesses to explore our high-end semiconductor manufacturing equipment range. Whether upgrading your facilities or establishing a new production line, our semiconductor equipment ensures that manufacturing processes are carried out with unparalleled precision. Our team of experts will assist in meeting the high levels of optimization the semiconductor industry demands. With seamless integration of our advanced tools into your operations, you can elevate your productivity and product quality to new heights. Contact us today for unmatched services.