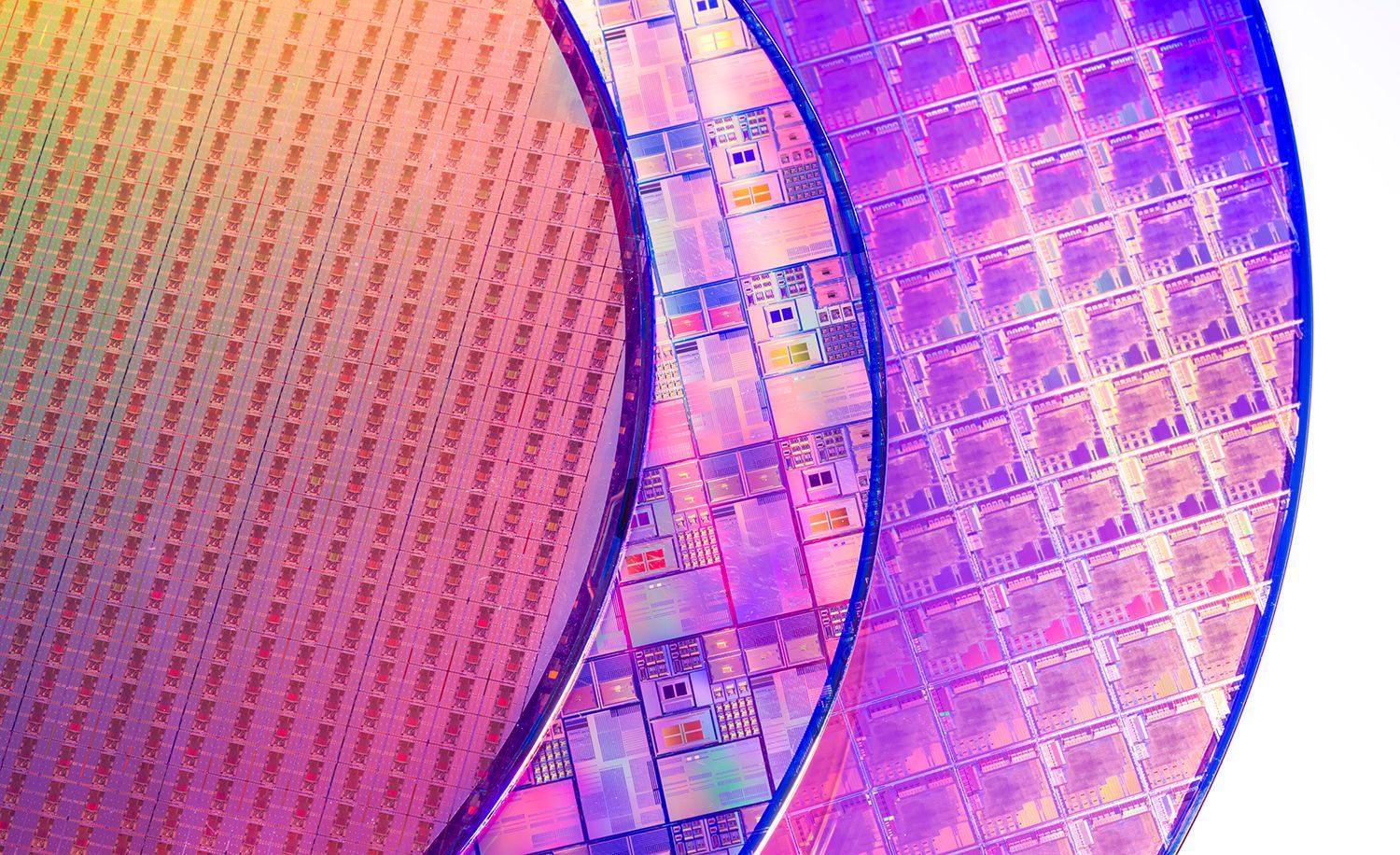

Vacuum lamination stands out as a superior process in the fabrication of semiconductor components, offering unmatched precision and adherence for advanced films and substrates. At GTI Technologies, our innovative vacuum lamination technique ensures that materials are bonded together without the presence of air bubbles or contaminants, which is critical for the integrity and performance of electronic devices. Our vacuum lamination process has become a key player in manufacturing complex, layered structures required in today's high-tech industry, enabling the production of smaller, more powerful, and more reliable semiconductor devices.

What Sets Vacuum Lamination Apart in the Fabrication Process?

Vacuum lamination is indispensable when working with sensitive components that cannot tolerate the slightest imperfection. As the best supplier of manufacturing equipment in the US, our vacuum lamination technology is designed to meet the industry's exacting standards.

Vacuum Lamination for Advanced Films

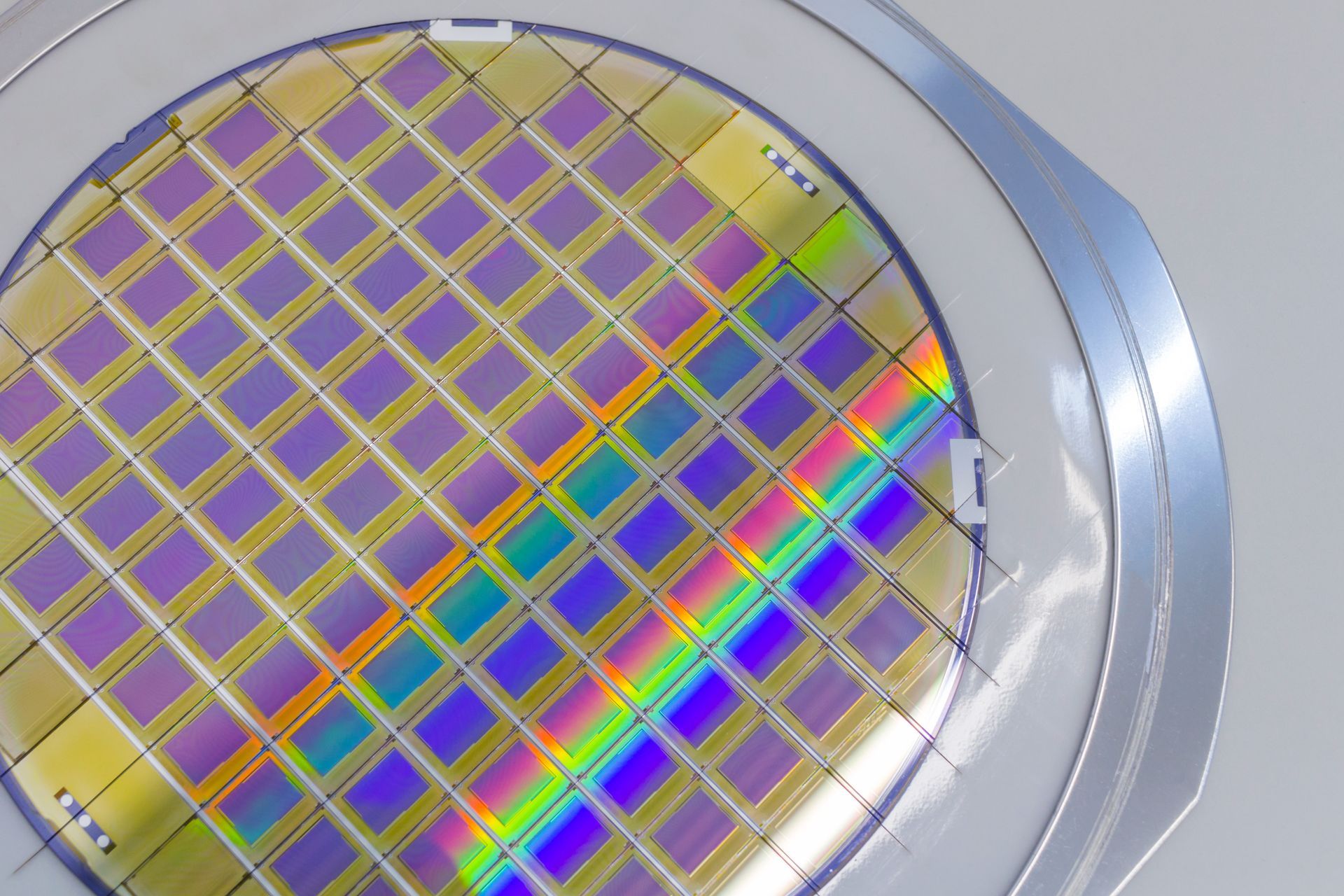

The precision of vacuum lamination is pivotal for modern semiconductor fabrication. Its ability to produce bubble-free, uniform layers differentiates it from other bonding methods or manufacturers seeking state-of-the-art semiconductor equipment. Our systems provide a solution that enhances the quality of tape lamination, which is crucial for protecting and insulating semiconductor wafers.

Tape lamination has moved far beyond the standard backgrinding application as companies have created new films for MEMsvs, bumps, pillars, and other advanced packaging applications. The Takatori TEAM approach provides the most innovative and capable solution for laminating these films, providing the highest quality lamination for the most demanding applications. Some of the lamination machines we provide include:

- Vacuum Lamination - Standard tape lamination generally rolls tape onto a wafer, but it is often better to laminate using a vacuum to achieve the highest quality lamination. The Takatori TEAM series of machine laminate wafers are in a vacuum chamber without rollers and with very low force. The result is even lamination that fills in even deep features but eliminates microbubbles. Lamination can be done at such low force that backside lamination is possible, even when using a non-contact chuck.

- Pre-Cutting Tape - Tape laminators usually laminate tape onto a wafer and cut the tape along the edge of the wafer, but the Takatori TEAM-series uniquely separates tape cutting from lamination. Tape is pre-cut on a separate stage and then is transferred to a vacuum chamber, where it is laminated onto a wafer. This not only provides for zero-tension lamination but also allows for “inner cutting,” a technique where the tape circle is cut to a slightly smaller diameter than the wafer. This avoids overhanging edges and applies the film only where needed.

- Multi-Layer Lamination—The tapTEAM series' tape pre-cutting capabilities open the door to multi-layer lamination, allowing customers to layer multiple layers of tape onto a wafer.

In conclusion, the Takatori TEATEAM series lamination machines provide a unique capability to customers looking for an advanced lamination solution. Our sophisticated wafer lamination capabilities ensure optimal outcomes for a range of applications within the electronics sector.

Learn More About Our Vacuum Lamination Capabilities

As a leader in vacuum lamination technology, we are dedicated to providing our clients with the very best solutions for their semiconductor fabrication needs. If you are looking to refine your production process and achieve superior product quality, we invite you to learn more about our advanced vacuum lamination capabilities. So please contact us if you desire personalized assistance or would like to discuss how our vacuum lamination systems can be integrated into your operations; our expert team is ready to support you in revolutionizing your fabrication process and achieving the high level of optimization that today's semiconductor industry demands. To learn how we can help further, navigate our “about us” page.