Diamond wire, originally developed for cutting hard, crystalline materials, offers a new solution for cutting core materials. The technology provides numerous advantages over traditional technologies including multi-axis machining centers and bandsaws. It is an effective tool for cutting a wide variety of materials quickly and efficiently.

Diamond wire technology:

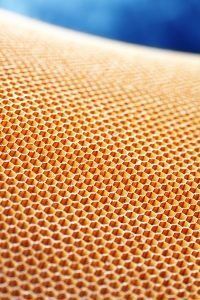

1. Reduces Damage – Diamond wire cutting, while effective for even the hardest materials, is a relatively gentle process when compared to the more aggressive, traditional machining methods. Diamond wire uses a very fine abrasive on a thin wire, and even fast cuts can leave behind pristine edges and surfaces. Delicate feathered edges are possible, with honeycomb cells left completely intact even on the sharpest angles.

2. Minimizes Kerf Loss – Diamond wire is thin, (the current standard for cutting composites is only ~0.350mm in diameter,) – minimizing material loss. Customers get more parts out of a given quantity of core material with diamond wire cutting, lowering costs.

3. Offers speed – Despite the gentle cut and thin wire, diamond wire technology cuts materials at high speed, even in thick and dense cores. The use of a multi-axis industrial robot with the Takatori TWR-300 Robot Wire Saw opens the door to cutting complex shapes on a relatively inexpensive platform, saving time and money.

4. Generates Fewer Particles – Diamond wire cutting requires no coolant and only generates a small amount of fine dust.

While new to the composites industry, diamond wire technology has been used extensively in industrial applications for almost 20 years, making it a mature, reliable technology. Contact GTI to learn more about how diamond wire can help you with your application.