Cable Saws

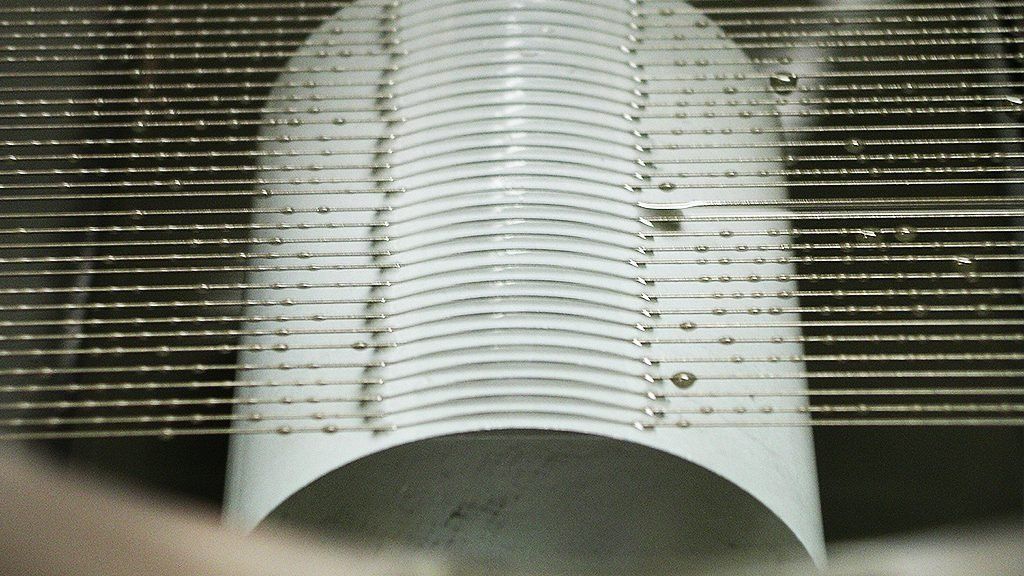

Cable saws stand at the forefront of cutting technology, providing a powerful and versatile solution for slicing through an array of tough materials with ease. At GTI Technologies, our robust cable saws are renowned for their durability and precision, making them ideal for construction, mining, and large-scale sculpting. Our cable saws operate by using a looped steel wire embedded with cutting diamonds or other abrasives, which allows them to cut through stone, concrete, and metal with remarkable efficiency. Their adaptability and strength make them indispensable assets in situations where conventional cutting tools fall short.

Which Materials Can Be Effortlessly Cut with Cable Saws?

Cable saws are engineered to tackle a wide range of materials, including but not limited to reinforced concrete, masonry, and various types of stone. The versatility of these saws is enhanced by their compatibility with other

wire sawing equipment, allowing them to integrate seamlessly into existing workflows.

Multi-wire saw users appreciate the added efficiency and reduced waste achieved when cable saws are part of their cutting arsenal. The wire sawing technique, empowered by cable saws, is particularly effective for making deep cuts and creating complex shapes, as it minimizes vibrations and delivers a cleaner cut than many alternatives. For professionals seeking top-tier cutting solutions, our professional

supplier of manufacturing equipment offers cable saws that provide the durability, precision, and power required for even the most challenging projects.

Our Process

01.

Work together with our customers and suppliers to clearly understand the application and our customer’s needs and potential solutions.

02.

Test our preferred solution, evaluate with the customer.

03.

Present and then deliver solutions on-time.

04.

Support our customers with training, spare parts, and ongoing engineering resources.

Order Your Professional Cable Saws

We take pride in supplying cable saws that enhance productivity and offer the precision necessary for high-quality results. To explore the benefits and features of our cable saws or to place an order for your business, feel free to contact us today. Our team is ready to provide expert advice and support, ensuring you select the best equipment to match your specific material-cutting needs. With our professional cable saws, you can expect to elevate your operation's cutting capabilities to a new level of excellence.

Contact us

Hours

Monday - Friday: 8AM-5PM

Service Area

6 Armstrong Road,

Shelton, CT 06484, USA