Backgrind Tape

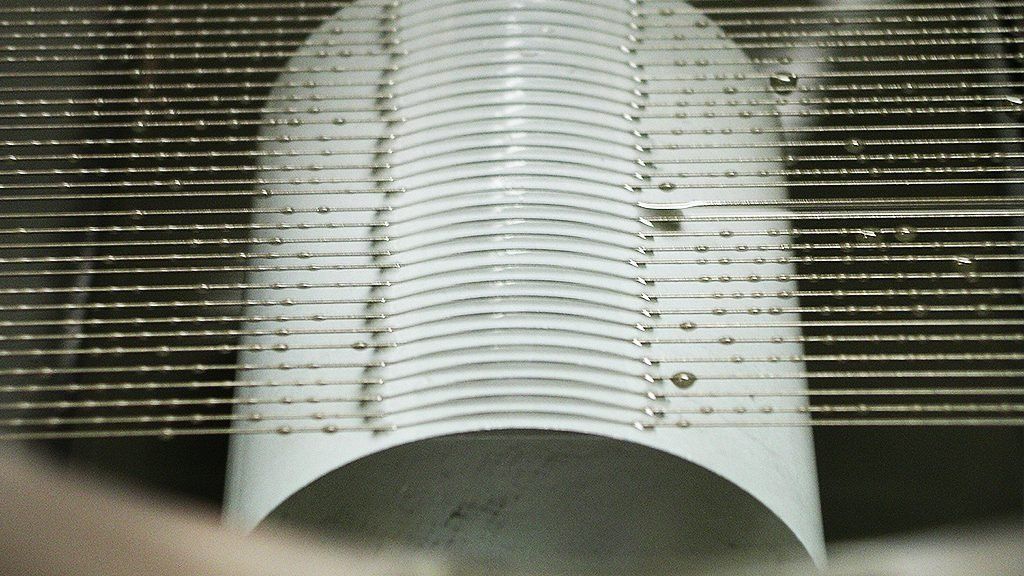

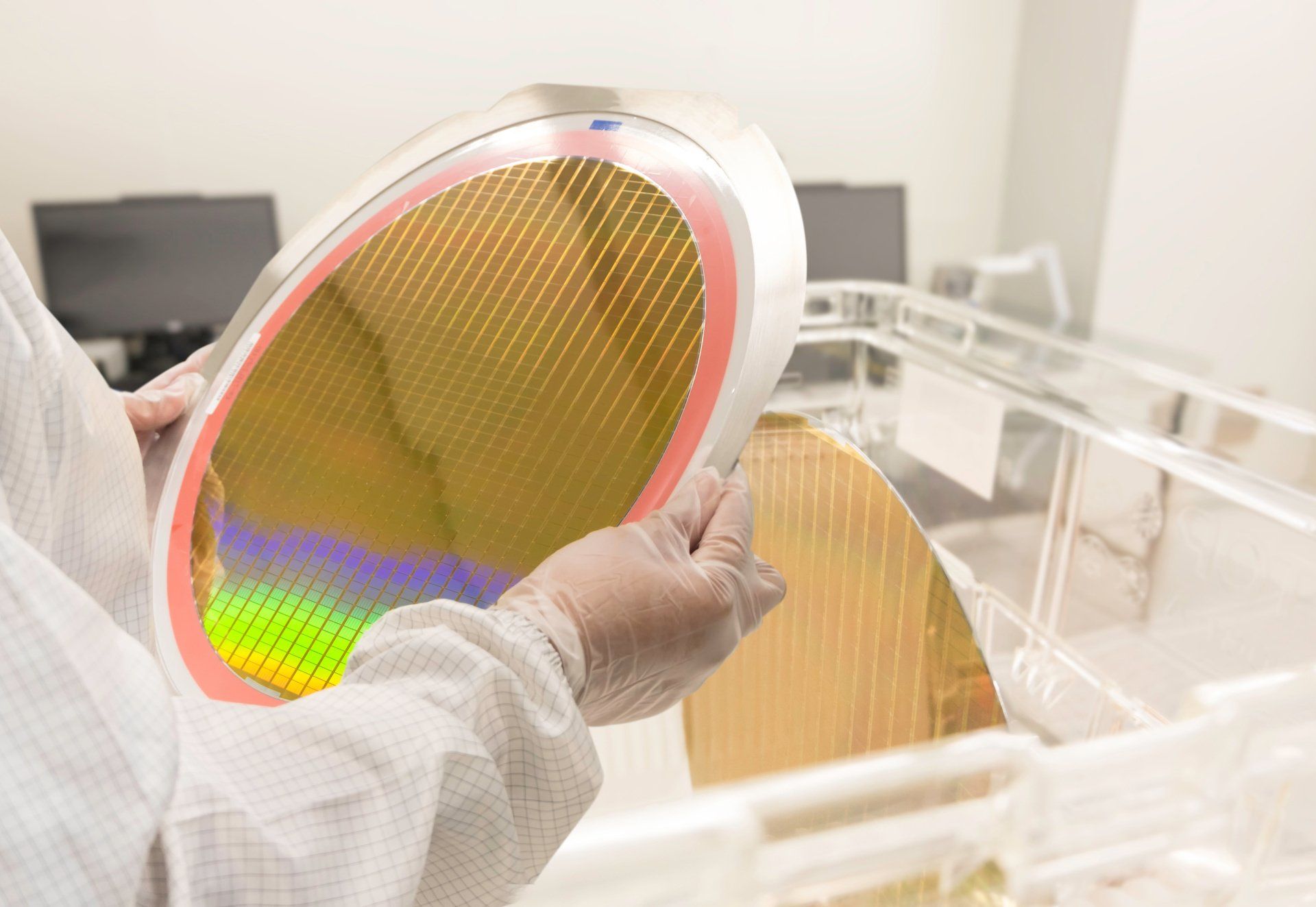

Backgrind tape is an essential component within the semiconductor manufacturing process, designed to safeguard wafers during the thinning stage known as backgrinding. At GTI Technologies, our specialized adhesive tape provides the necessary support to delicate wafers, preventing breakage and surface damage that could otherwise occur from the mechanical stresses of grinding. The use of backgrind tape is critical in maintaining the integrity of the wafer as it undergoes various levels of stress, ensuring that high-quality, defect-free wafers are produced for subsequent processing steps.

Benefits of Background Tape

The benefits of utilizing high-caliber backgrind tape in semiconductor fabrication are numerous. Backgrind tape not only protects the wafer surface from potential contaminants and damage but also aids in maintaining wafer uniformity and flatness, which is essential for subsequent processing steps like permanent bonding or metal liftoff. By employing backgrind tape from our trusted supplier of manufacturing equipment, manufacturers can ensure a reliable process that yields consistently high-quality results. Moreover, backgrind tape is designed to withstand various chemicals and temperatures that wafers are exposed to during the semiconductor equipment processes, highlighting its importance in the production of semiconductors. We provide top-of-the-line backgrind tape solutions that are tailored to meet the stringent requirements of the semiconductor industry. Our backgrind tape is engineered for optimum adhesion, cleanliness, and ease of removal, facilitating a smooth transition between manufacturing stages.

Our Process

01.

Work together with our customers and suppliers to clearly understand the application and our customer’s needs and potential solutions.

02.

Test our preferred solution, evaluate with the customer.

03.

Present and then deliver solutions on-time.

04.

Support our customers with training, spare parts, and ongoing engineering resources.

Order Your Backgrind Tape

If you're looking to enhance the protection of your semiconductor wafers during the backgrinding process, order your backgrind tape from us. For more information about our products or to place an order, contact us today. Our dedicated team is ready to assist you with selecting the best backgrind tape to match your specific needs, ensuring that your semiconductor production is seamless, efficient, and of the highest quality. Call us today for any metal liftoff service you might require.

Contact us

Hours

Monday - Friday: 8AM-5PM

Service Area

6 Armstrong Road,

Shelton, CT 06484, USA