Distributor of Advanced Manufacturing Equipment

With over 45 years of experience as a manufacturing equipment supplier, we have established a reputation for excellence across North America and Europe. We pride ourselves on providing high-quality machinery that meets the evolving needs of modern industry. At GTI Technologies, our extensive catalog includes everything from essential hand tools to complex CNC machines, ensuring that we supply the necessary equipment, whatever your manufacturing requirements. Our expertise has been honed over decades of service, equipping a diverse range of industries with the machinery they need to succeed.

Our Expertise as a Supplier of Manufacturing Equipment

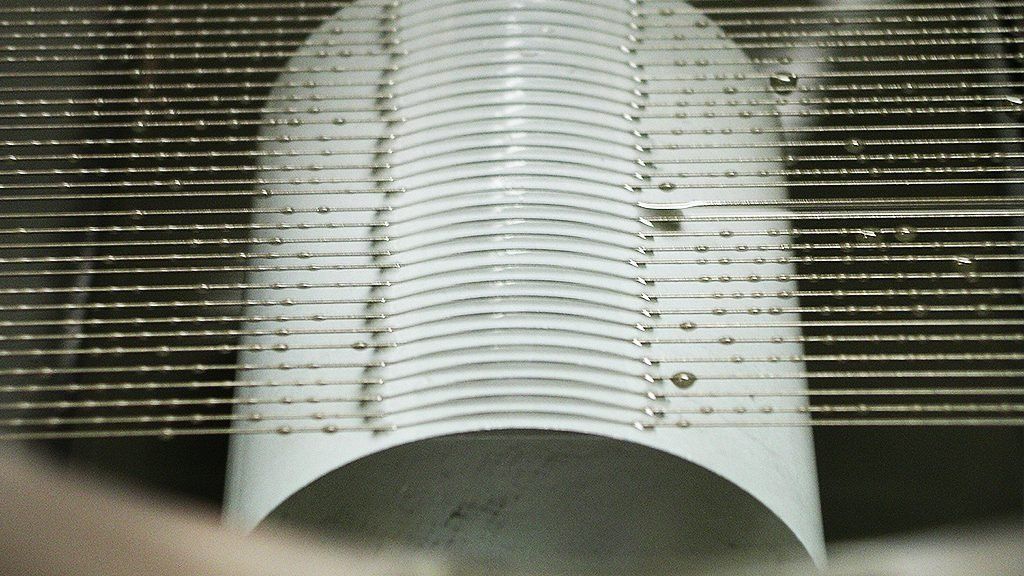

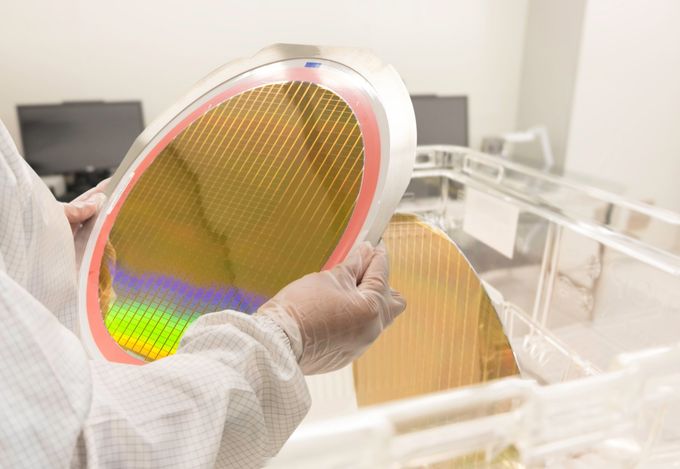

As the best supplier of semiconductor processing equipment, our longevity in the industry is a testament to the quality of our commitment to delivering and supporting machines with precision. We've equipped clients across North America and Europe with advanced multi-wire saws that streamline the semiconductor manufacturing process.

Delivering The Best in Global Manufacturing

GTI Technologies was founded in 1978 to deliver the best manufacturing equipment from suppliers in Europe and Japan. We provide sales, engineering, and spare parts for customers across North America and Europe, delivering and supporting machines for semiconductor manufacturing and advanced material processing.

Our Process

Our expertise extends to wire sawing technologies that cater to various applications, ensuring that every cut is made with professional accuracy. Our robust cable saws are engineered to handle the most challenging projects for the construction and mining sectors. As we are a company centered on customer satisfaction, here is the process we follow when it comes to satisfying our client’s needs:

01.

Work together with our customers and suppliers to clearly understand the application and our customer’s needs and potential solutions.

02.

Test our preferred solution, evaluate with the customer.

03.

Present and deliver timely solutions to support our customers with training, spare parts, and ongoing engineering resources.

Our metal cutting wire options offer versatility and strength for intricate metalworking tasks. As your trusted supplier, we're not just about delivering machines; we're committed to providing ongoing support to ensure your operations run smoothly.

Choose Us as Your Supplier of Manufacturing Equipment

When you choose us as your manufacturing equipment supplier, you select a partner with a proven track record of over 45 years. Our extensive experience ensures that we understand the intricacies of your industry and can provide equipment solutions that deliver tangible benefits. We take pride in producing and supporting machines across North America and Europe, providing the reliability and service excellence that your business deserves. For more insight into our offerings and how we can assist you, learn more about us. Contact us today if you're ready to enhance your manufacturing capabilities with a seasoned industry leader. Let us put our experience to work for you, delivering and maintaining the high-quality equipment you need to drive your business forward.